Plant tissue culture is a highly specialized field that demands advanced technical expertise and top-tier infrastructure for commercial success. With this in mind, we have developed state-of-the-art facilities that fully comply with the stringent requirements of regulatory authorities, including the Department of Biotechnology, Government of India. Our infrastructure and processes adhere to international standards and are ISO 9001-2008 certified, ensuring the highest levels of quality and operational excellence.

Infrastructure

Tissue Culture Lab

Plant Tissue Culture Laboratory

Our State of the Art plant tissue culture laboratory is one of the well-designed and fully compliant to the Department of Biotechnology, Government of India guidelines. The Laboratory is bifurcated into sterile and Non Sterile areas. Plant Inoculation Room, Media Storage room and Growth Rooms are in sterile area (Class 10,000 & 100,000). In the non-sterile area the sections like Media preparation area, Autoclave Room etc. are operating. Apart from that, semi-automatic bottle washing and rinsing machines, Reverse Osmosis system coupled with demineralization unit to provide water with required purity levels are also part of our High-Tech venture. A captive power generating unit for 100% power back up is also provided to meet any eventuality.

Media Preparation Area

The media preparation room is equipped with fully Automatic Media Preparation machine coupled with semi-automatic Media Dispenser. The media production capacity of this section is 500 Liters per day. This section is fully equipped with all the modern instruments like Digital pH Meter, Electronic Micro and Macro weighing scales, Online Conductivity Meter, RO Water Purifying system, DM water units etc.

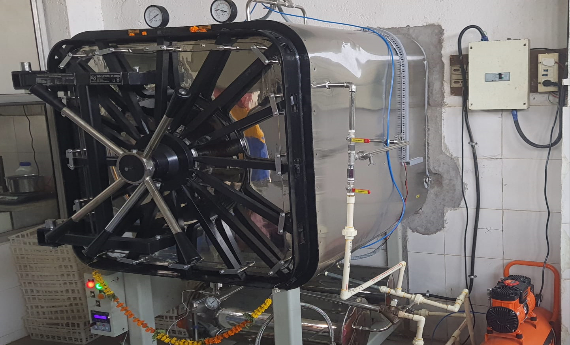

Autoclave Room

The autoclave room is situated adjacent to the media preparation area. The fully Microprocessor controlled steam autoclave has the capacity to sterilize 75 liters of media at a time. The microprocessor based controlling system of our autoclave enable us to program the machine as per requirements, which safeguard against the problem of under sterilization or over sterilization.

In Process Quality Control (IPQC)

Quality is a prime concern to us at every step, so is the quality check at every culture cycle. Highly trained technicians thoroughly inspect every culture for any bacterial or fungal contamination and ensure that only clean cultures pass to the next cycle.

Plant Inoculation Room

Plant inoculation area is the epicenter of any tissue culture activity and cleanliness level of this area is maintained at Class 10,000 level and is centrally air-conditioned. Twenty One Double Laminar Air Flow Machines are provided and Forty Two Technicians can process the plants at a time to meet production requirements in stipulated time.

Growth Room

Our growth rooms are with tailor made racks, lighting and other equipments. In the growth rooms environmental conditions like temperature, humidity, light and its intensity are precisely controlled for the optimum growth of plants.

Green house